NIMPHEA

Next-generation MEA for aviation

The NIMPHEA project will develop a new-generation Membrane Electrode Assembly (MEA) – the central component of Proton Exchange Membrane Fuel Cells – compatible with aviation applications. This is a key enabling technology for the deployment of fuel cells in aviation.

The project has been funded by the Clean Hydrogen Partnership. The research will be carried out over a 4-year period starting in January 2023.

Rationale

Air traffic is constantly increasing, and aviation is responsible for a significant proportion of greenhouse gas emissions. The European Union has set the objective of achieving carbon neutrality by 2050, and the Advisory Council for Aeronautic Research in Europe (ACARE) is targeting a 75% reduction in aviation emission in the next 30 years.

Hydrogen-based fuel cell systems are one of the most promising solutions to deliver energy to aircrafts without emitting CO2 and NOx. Fuel cells enable the conversion from chemical energy contained in a fuel such as hydrogen into electricity. Proton Exchange Membrane Fuel Cells (PEMFC) have been widely developed for on ground transport applications over the last 20 years. The Membrane Electrode Assembly (MEA) is the core component of this technology.

Today, fuel cell systems developed in the automotive industry are operated at a typical temperature below 100°C. This operating temperature generates constraints that make their integration in the aircraft environment extremely difficult due to thermal management issues. The development of a new-generation MEA, working at temperature above 120°C , is one of the keys to unlock fuel cell applications for aviation industry. In this context, the NIMPHEA project will develop and validate a new-generation, high-temperature MEA that meets the requirements of fuel cells for aviation.

Picture credit: Antoine Heusse / photo-h for Safran

Objectives

The overall objective of the NIMPHEA project is to develop and validate at TRL4 a new-generation high-temperature Membrane Electrode Assembly (MEA) addressing the challenging requirements of fuel cells for aviation. The developed MEA will operate above 120°C and thus overcome the thermal management issues of high-power systems

Specific objective 1

Design the concept of the new-generation disruptive MEA operating above 120°C and develop its components

Specific objective 2

Upscale the small-scale MEA in view of preparation for manufacturing and future integration at fuel cell stack level

Specific objective 3

Validate and demonstrate the performances of the developed new-generation MEA at TRL4

Specific objective 4

Evaluate and validate the suitability of the new-generation MEA by performing a complete life-cycle assessment

Expected results

New-generation MEA components

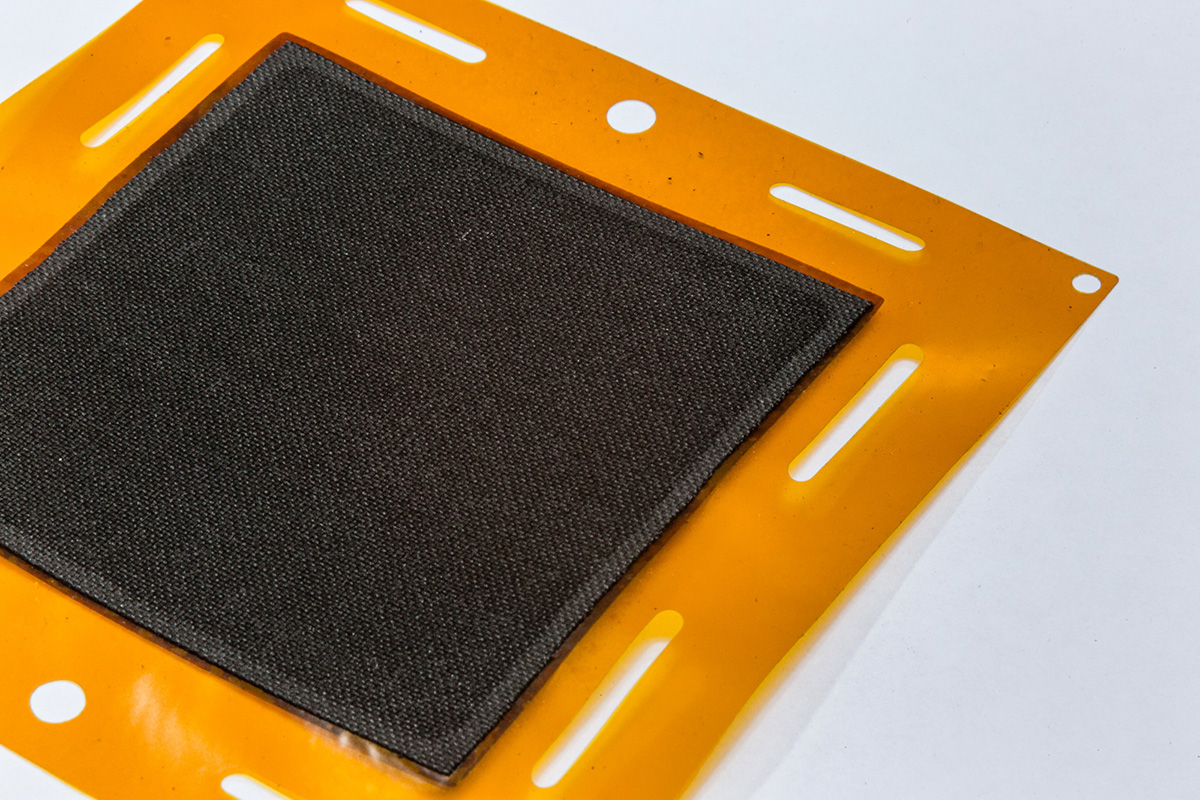

Catalyst layer, membrane and gas diffusion layer optimised and tested, operating above 120°C

MEA containing new-generation components

- assembled, tested and validated at TRL4 in single cells

- improved performances to enable integration in FCs for aviation

Aviation-relevant test procedures

Life-cycle assessment

Impact

NIMPHEA will develop, manufacture, test and validate at TRL4 a new-generation of MEA, thus paving the way towards fuel cell operation at temperatures higher than 120°C and therefore to unlocking the full potential of fuel cell disruptive technology uptake in applications with high power generation systems requirements.

Demonstration of the developed technology under laboratory test conditions will prove the feasibility of the concept and pave the way towards further maturation within the Clean Aviation programme for integration into a specific architecture for demonstrations. This is a critical path for the demonstration of future fuel cells products in aviation.

Consortium

The NIMPHEA consortium brings together leading fuel cell system developers (Safran Power Units and Safran Tech) and an experienced MEA industrial actor (Advent) to lead the architecture definition, requirements and design activities. Recognised academic and research institutions (Université de Strasbourg, Fraunhofer ICT, Commissariat à l’énergie atomique et aux énergies alternatives – CEA , Centre national de la recherche scientifique – CNRS) will support the above-mentioned industrial partners with the characterisation, development, manufacturing, modelling and testing of the individual components of the MEA and of the upscaled MEAs. Finally, the life-cycle costing, environmental life-cycle assessment and the eco-efficiency benchmarking will be conducted by IMDEA Energy, a Spanish research institute expert in the energy field.t

Latest News

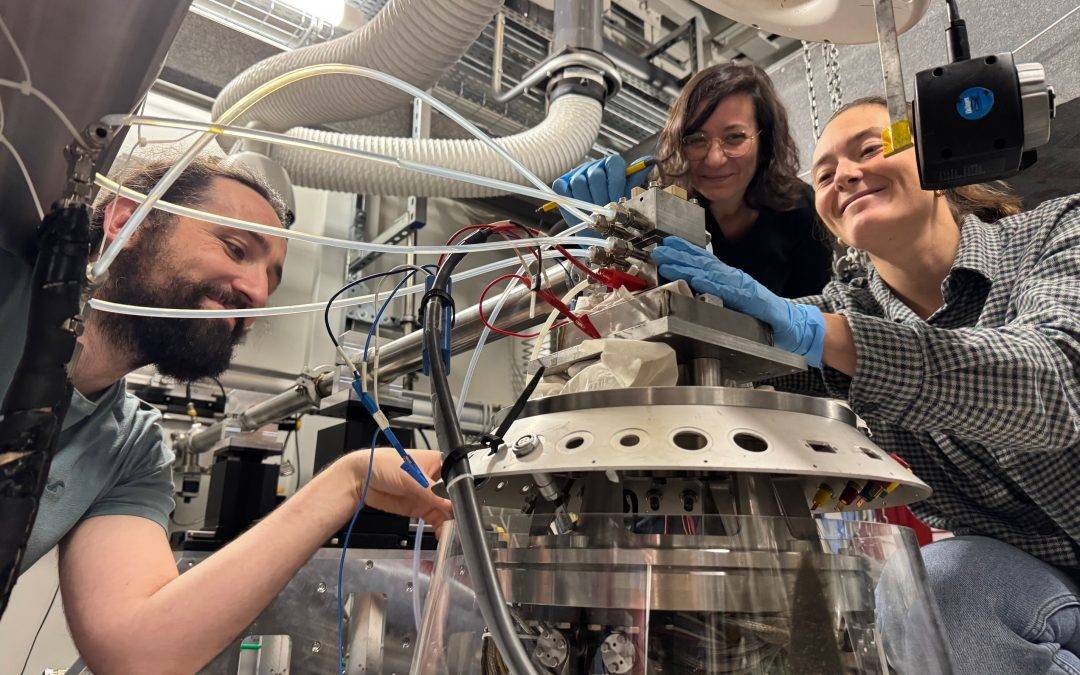

NIMPHEA advances with Operando Experiments at the ESRF Synchrotron

Within the NIMPHEA project, we are conducting operando synchrotron experiments on High-Temperature Proton Exchange Membrane Fuel Cells (HT-PEMFCs) at the ID31 beamline of the European Synchrotron Radiation Facility (ESRF).

NIMPHEA Consortium holds General Assembly meeting at IMDEA Energy

The NIMPHEA consortium gathered at IMDEA Energy Institute (Mostoles, Spain) for its latest General Assembly meeting, bringing together all partners to review progress and plan the next steps in the project’s development.

NIMPHEA Project at Vienna Aviation Days 2025

On 7-8 July 2025, the NIMPHEA coordinator participated to the Vienna Aviation Days 2025 organised by the ExFan project.